When you want to cut plexiglass, several cutting tool options will be recommended. The question is, are they all accurate in performing this task? The only way to know is to try them practically, but economically it is not an option. You know how fragile and brittle plexiglass is, so I recommend using a jigsaw.

Of course, it has been tried, and it’s safe to say it is the best tool to use when cutting plexiglass. A jigsaw is handy when it comes to handling several tasks. A jigsaw is a small handheld tool with a straight blade. It is normally used in workshops and garages for precise cutting, making curves and angles accurately on any piece of material.

I will show you how to cut plexiglass with a jigsaw along with a few tips and recommendations to help you every step of the way.

What Is Plexiglass?

Plexiglass is transparent plastic commonly known as acrylic glass. It normally goes by different brand names like plexiglass, Perspex, Acrylite as well as Lucie.

This plastic usually comes as plexiglass sheets, and they are very lightweight and don’t shatter easily like the case with glass.

- Multipurpose Project Use – These acrylic plexiglass sheets can be used for a range of DIY and professional projects, such as laser engraved signage, hobby display cases, art protector, tabletop protector, home décor, shelving, and more.

- High-Clarity Grade A Clear Finish – Along with improved weather and UV resistance, our transparent acrylic sheets offer superior visual clarity to make it easier to see through. Protective paper included.

- Long Rectangular Frame & Enhanced Durability – SimbaLux heavy-duty plexi glass panels are tougher than standard glass with about 0.125” (1/8 inch) or 2.7mm to 3.3mm (3mm nominal) thickness that offers better indoor and outdoor resilience. Sized at 12 inches by 24 inches, these versatile acrylic plastic sheets can be used as is or cut to suit almost any job.

- Easy to Cut and High-Quality Cell Cast Design – With no melting point, cutting through our thick acrylic boards with a laser, tablesaw, jigsaw, drill, router, or bandsaw is quick and easy. The cell cast version offers clean cut edges without burrs, sharper laser engraving, higher resistance to scratch and chemical solvents.

- 1-Year Warranty – Just send us a message if the product malfunctions before 1-year after the purchase date and we will either refund you or send you a replacement.

While it doesn’t shatter easily, it can easily get scratched if there is no scratch-resistant layer applied on top of the manufacturer.

Most experts recommend using a laser to cut this material because it leaves a clean cut than most tools.

However, the absence of a laser, many people prefer to use a jigsaw because it is the best substitute for the laser.

Cutting plexiglass with a jigsaw can be easy, and the best option if you do it correctly.

What Are The Best Ways Of Cutting Plexiglass?

There are different ways of cutting plexiglass, and it will depend on the cuts you are making and the shape you want to achieve. Below are the different ways.

Ways To Cut Plexiglass

- For curved cuts, use a jigsaw because it is strategically positioned. The jigsaw being small and handheld, makes it easy to maneuver to achieve such cuts.

- When dealing with plexiglass, which is brittle, you will have to use a band saw to get the job done.

- Long straight cuts can be achieved by using a table saw blade.

- If you don’t have a jigsaw, table saw, or even a band saw, then using a hack saw can work for you.

Types of Saws to Use for Various Types of Cuts on Plexiglass

- Band saws are best for cutting curves in flat sheets and when the formed parts are roughly trimmed.

- The table saws are best for cutting Plexiglas sheets o close dimensions. These usually vary in size, and the most commonly used is a medium-duty model.

- Radial saws and swing saws come handy when you want to make angle cuts plus cross cuts when dealing with narrow Plexiglas sheets.

- Panel saws that come in two types are best to use when you want to prevent the risk of damaging the Plexiglas by cracking it. They are best because of the way the sheet is placed on the table and how the saw feeds through it.

- Scroll saws can be used when cutting sharp radii plus closed holes in the thin Plexiglas sheets.

- Saber saws are also great for cutting curved cuts or straight cuts.

Why Should You Make Use Of A Jigsaw?

While plexiglass is durable, it tends to break into large pieces when too much pressure is applied to it. The pieces won’t have sharp edges on them like the case with glass, but handling it with care while cutting is very important.

This is why you should make use of the jigsaw because it is small, and you don’t have to use much force when feeding the blade into the Plexiglas sheet.

Why Use A Jigsaw? A jigsaw is great to use because of many other different reasons. One of them being its blade doesn’t heat up a lot, which can cause the Plexiglas to melt.

Remember Plexiglas has a melting point of about 320 degrees. Although it will stay solid for long, it will melt when you use a tool heating up more to reach the 320 degrees.

Another reason you can cut Plexiglas with a jigsaw is to make both curved lines and straight cuts. Also, the tool allows you to cut across large surfaces of Plexiglas pieces. These are the advantages that a jigsaw has over most saws.

When to Use a Jigsaw for Cutting Plexiglas

Like I mentioned before, there are different types of saws used to cut Plexiglas. However, most of them are only good at making certain cuts. The jigsaw, on the other hand, allows you to make different cuts at different angles, making it a better tool.

- You can use this tool when you want to cut Plexiglas pieces in a straight line while making a curving motion which other saws can’t do.

- It is also best used when you want to start cutting the piece from the middle instead of coming in from the edges.

- Use it when you want to cut straight but at different angles or when you wish to cut in circular/any shape motion.

How To Cut Plexiglass With A Jigsaw – Learn The Accurate Cutting Guide

Safety First

When cutting Plexiglas with a jigsaw, you will have to get a good surface perfect for supporting your Plexiglas properly throughout the whole process.

Make sure the material is secured so as not to drop it while you cut. It will save you from getting injured and destroying your project.

Protection Gear

The next thing is to gear up by wearing protective gear. Wear safety glasses to protect your eyes from any flying objects may land to your eyes when breakages occur. Also, make sure to wear work gloves to avoid the risk of getting cut while you work.

- WARRANTY INCLUDED. If we dont meet your expectations or you have an issue we are happy to help- When it comes to our protective eyewear, we make a point of using nothing but premium quality materials, as well as state of the art production processes and strict quality control! Our motivation is to provide you with products that you will love . If however you dont feel satisfied with something please get in touch we are happy to help make your experience a positive o

Before You Start Cutting

Once you have followed the safety precautions, go on to the next step, and this is to apply masking tape on both sides of the cutting area. This will prevent the piece from chipping as you cut.

However, in case the Plexiglas comes with protective plastic, then it is not necessary to apply the masking tape. Protective plastic or masking tape is applied to secure the piece in place as you contact it.

- Choose The Right Jigsaw Blade

Next, choose the best saw blade for plexiglass because the wrong one tends to chew upon the material. Look for a fine and shallow blade to give you smooth cuts even when you start to cut the piece with high speed.

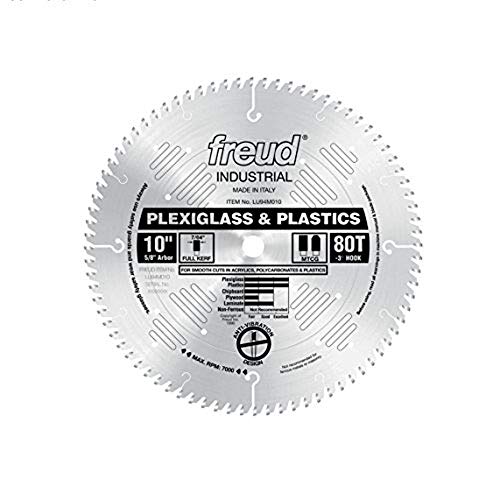

- Exclusive Freud TiCo Hi-Density Carbide with modified triple chip grind (MTCG) tooth design enables clean smooth cuts while eliminating melting

- Negative hook angle produces a superior finish without grabbing the material

- Ideal material thickness: ╝ to 1-5/8

- Laser cut Anti-vibration vents drastically reduces vibration extending blade life

- Recommended for plexiglass, plastics, chip board, plywood, and laminates, Impor

When using a jigsaw, experts recommend using a 10 TPI bi-metal jigsaw blade.

It is also safe to use an extremely sharp hollow groundwood blade. Stay away from very fine metal blades because they will clog into the material while you cut, causing the plastic to melt because of the heat.

When cutting Plexiglas, choosing the blade for use can be an essential task for you to achieve excellent results.

How To Approach The Accurate Cut With A Jigsaw – Follow The Proper Way

Mark The Plexiglas Workpiece And Clamp It Securely

Mark the plexiglass you wish to cut using a marker. By marking the piece, you will be able to feed the blade right where you want to pass it. After, make sure the piece is clamped down securely onto the surface you are going to from.

Fit The Right Jigsaw Blade And Make A Test Cut

Once you are through, fit the blade you are going to use for cutting into the jigsaw. Once it is properly fitted, use it to make a test cut first.

Practice On A Smaller Piece

Get a small piece of Plexiglas you don’t need for your test cut before cutting the larger piece. By practicing first, you will get the hang of it before the actual cut. It will also help you avoid making mistakes on the final material.

Cut With Some Momentum

Begin cutting the smaller piece with some momentum because failure to do so will make the blade of your jigsaw to jam into the piece. With the wrong momentum, you will end up messing the accuracy. So as you practice, try getting the right momentum you will use on the final piece.

Approach With Some Speed

Aside from approaching with momentum, you also need to approach the piece with the right speed. You have to fire up the jigsaw blade first so it can pick up speed before it makes contact with the Plexiglas piece. Starting the jigsaw with the blade in contact with the piece can damage it greatly.

Cover The Cut Line With A Masking Tape

When you practice, you can then move onto the actual piece you wish to cut. Start by covering the cut line you made with masking tape. The tape will prevent the piece from chipping at the edges as you cut.

Cut Your Workpiece Along The Marked Cutting Line

Next, start cutting through the workpiece while following the cutting line you made. Your jigsaw will, when handled well, should be accurate and cut through the line well.

Approach The Finishing With Care

As you cut to the finish, make sure you approach it with care. Keep the momentum and the speed to keep the finished edge smooth like the rest of the cut.

Remove The Masking Tape Smooth The Edge

Once you achieve the right cut you wanted, you can now remove the masking tape from the cut. The cut should be smooth and free from chipping. Use sandpaper to smooth the edge of the cut to get the smoothest edge.

How To Avoid Melting When Cutting The Plexiglass Cut With A Jigsaw

Cut Steadily

Approach the cut steadily and not too slowly. Be fast, but not too fast to destroy your accuracy. Cutting at a slow pace will make the jigsaw blade transfer heat to the Plexiglas, causing warping to make cuts uneven.

To avoid this scenario, don’t move slowly. This is also the best way on how to cut thick Plexiglas because it’s more prone to melting.

Don’T Pause

Never pause as you cut through Plexiglas as it can also be as hazardous as cutting slowly. Don’t let anything distract you as you cut, leading you to pause because then you will leave the blade in one place, causing it to leave the heat in that particular area.

Methods To Avoid Overheating

- Use the right blade

- Run your jigsaw at the right speed

- Don’t use the jigsaw blade to cut Plexiglas pieces thicker than the tool’s capacity

How to Prevent Plexiglas Breakage

Another problem that may arise as you cut Plexiglas is breaking or cracking. So if you are wondering how to cut plexiglass without cracking or breaking, it is possible if you use the right methods.

Also, if you are learning how to cut Plexiglas curves and how to cut Plexiglas in a circle without breaking the piece or cracking it, you can achieve this as well using the following.

Use A Cooling Lubricant

Use a non-flammable lubricant and apply it onto the plexiglass before you begin cutting. Lubricant helps to reduce friction during cuts that tend to cause heating. It also ensures you get a smooth cutting motion.

Use Water

If you don’t have any lubricant, water can be another simple option. Keeping sprinkling water on your Plexiglas, especially around the area you are cutting. This will keep the blade cool as you work.

Apply Masking Tape

Like I mentioned before, applying masking tape prevents cracking of the cut edges. The tape protects those edges you are cutting while providing the jigsaw blade a smooth path to cut through.

Use Your Jigsaw To Cut The Plexiglas

Once you have established everything from safety to the working area, start cutting the plexiglass with your jigsaw. Follow the above steps from the momentum to the speed needed to cut through the Plexiglas.

When cutting, you may feel a bit of resistance, and you must switch off the saw immediately and take it out. Start it a little later and feed it back into the piece.

Cleaning The Edges

The edges you get after the cut may not be as smooth as expected, but it shouldn’t be a problem. Fix this by using sandpaper to make them smooth. The sandpaper will clean up the edges nicely.

Check These Frequently Asked Questions (FAQ) and Learn More

Q: When To Use Other Saws To Cut Plexiglass

A: You will need to use other saws to cut plexiglass when you can’t achieve certain cuts using a jigsaw. Some cuts require you to place the Plexiglas in a certain way, which you may not be able to get when using a jigsaw.

Q: When To Use A Band Saw To Cut Plexiglass

A: Use a band saw when you want to make continuous cuts. A band saw has a continuous blade that can also move in one direction making such cuts quick and easy. It will not make the piece chip as the case with a jigsaw.

- 2.8 amp motor rotates the blade up to 2460 feet per minute

- Create cuts up to 3-5/8 inches deep and 9 inches wide

- Uses 62-inch blades anywhere from 1/8 to 3/8 inches in size

- Spacious 12 x 12 inch work table bevels up to 45 degrees

- Includes a 3/8-inch-wide blade, a dust port, a fence, a miter gauge and a 2-year warra

Q: When To Use A Table Saw To Cut Plexiglass

A: Cutting plexiglass with table saw will allow you to achieve long and straight cuts. The piece is placed on the surface of the saw’s table securely before the cut is made.

- Flexible - power of corded. Freedom of cordless. The worlds first battery that automatically changes voltage when you change tools

- 24 of Rip capacity for ripping 4x8 plywood or osb sheets

- Rack and pinion telescoping fence rails make fence adjustments smooth and accurate

- Metal roll cage base offer greater durability than plastic Bases

- Power-loss reset prevents accidental re-starts following a power disruption when the switch is left in the on position

- Battery & Charger Sold Separat

Q: When To Use Hack Saw To Cut Plexiglas

A: Only use a hack saw to cut Plexiglas if you don’t have any other saw recommended for cutting it. A hack saw is the last tool you can use, which is not recommended because the end results will not be good.

- BLADE SECURITY: Solid metal frame of the hand saw is designed for tension up to 225 lbs.

- DEEP CUTS: The handsaw has 12-inch fixed blade length and 4.375-inch cutting depth

- FLUSH CUTS: 90-degree and 180-degree adjustable blade angles allow for flush cuts

- COMFORT: Large, comfortable tension knob with a full-grip han

Q: How To Cut Plexiglass With A Circular Saw

A: Wear safety gear and place the Plexiglas onto the workbench. Mark the cutting line and then bring it to the circular saw. Aim the saw on the piece and wait for it to increase the speed. Now push the saw into the sheet in a slow and smooth motion to cut through it.

- The product is 7-1/4 Circle Saw/Brake

- Easy to use

- The product is manufactured in China

- Rip fence for use with most DEWALT circular saws

- Provides smooth, precise results

- simple to fasten and designate distance from blade to fe

Q: How To Cut Plexiglass With An Oscillating Tool

A: Mark the Plexiglas sheet with a cutting line. Secure the sheet onto a workbench and bring the oscillating tool. Before feeding it into the sheet, turn it on to the right fast speed and move it slowly through the piece to the finish.

- The 3-speed selector of DEWALT 20V tools allows users to choose their speed setting based on application.

- Brushless motor of DEWALT oscillating tool delivers up to 57% more run time over brushed

- Dual-Grip variable speed trigger of DEWALT cordless tools gives users ultimate speed and application control

- Universal accessory adapter for use with most oscillating tool accessory brands. Oscillations/min: 0-13,000/ 0-17,000/ 0-20,000 OPM

- Quick-Change accessory system allows blades and attachments to be changed quickly without wrenches

- Bright LED illuminates dark work surfaces for accurate cutt

Q: How To Cut Plexiglass With Rotozip

A: The rotozip looks like a drill, but I will cut well like a saw. Mark your piece and the clamp I firmly into the surface. Choose the right bit to cut that can cut the Plexiglas and then turn on the device. Once it gets the right speed, feed it into the sheet to achieve your cut.

- DEWALT rotary tool features tool-free bit change for fast and easy bit changing without a wrench

- Turn-on/Bump-off switch of DEWALT cut out tool allows user to easily shut tool off

- 5.0 amp, 30,000 rpm motor provides more cutting power

- Slim body design and ergonomic for less fatigue over prolonged use

- Dust-Sealed Switch protects against dust ingestion for longer switch life

- Jam-pot construction provides jobsite durabil

Q: How To Cut Plexiglass With A Router

A: Set up the work area and then mark the Plexiglas. Position it on the workbench and then prepare the router. Turn the tool on and then set it to the right speed. Bring it down to the sheet and move it in a straight and steady motion till the finish.

- Dual LED lights help illuminate the work surface

- Depth adjustment ring allows for fast and easy height adjustments

- Electronic brake slows the motor down faster after the unit is shut off; Speed 16,000 to 25,500 rpm

- Variable speed dial allows the user to match speed of the router to the application

- Soft start motor with full time electronic feedback allows the motor to maintain speed during c

Q: How To Cut Plexiglass With Dremel

A: Start by marking the Plexiglas to get a cut line. Next, clamp the sheet down securely so that it doesn’t move as you cut. Plugin your Dremel and turn it with a 6 or 8-speed setting. Now feed its blade into the sheet and begin to cut.

- ★ Quick Change Drill Chuck - Come with 3 Jaw Universal Chuck applying better stability on your projects, allows you to quickly and easily change accessories on Rotary machine tool freely. GOXAWEE Multi Chuck accepts accessories from 1/64” to 1/8” shank, wider compatible than others. Ideal when the application requires numerous accessory changes.

- ★ 140pcs Attachment & Accessory - Flexible Shaft holds like a pen for your precise projects. Cover Shield provide better protection for cutting and grinding. Drill Locator helps for precision work on wood. Diamond Cutting Wheel is the best tips for glass, ceramic, floor tile etc. Versatile accessories include a pair of extra carbon brush, rescue you from searching new set and saving money.

- ★ Variable Speed & Compact - Variable speed dial is easy to use. The Variable Speed Adjustment Knob showing 5 Step Speeds from 8,000 to 30,000 RPM. By adjusting the speed you can make delicate engravings on wood, glass, metals, plastics, tile and other materials with control easily. Its ergonomic compact rotary tool design makes it handhold size, lightweight, not make the loud noise.

- ★ High-Performance Craft Tool - Perfect for sanding, polishing, cutting, shaping, drilling, deburring, grinding, cleaning, engraving, trimming etc, and enabling you to achieve different crafting work efficiently. Whether you are repairing home tasks or lighting your creations, this is really a worth value investment.

- ★ Amazing Gift for DIY Enthusiasts - Packed in a solid carrying case. It’s more solid, falling resistant and moisture-proof. Machine and accessories are well organized in, easy to place, light weight, portable for carrying. GOXAWEE Rotary Toolkit G4007 is great for the DIY craft and small family projects. It’s also the gift for the people who are keen on handmade stu

Conclusion

Learning how to cut Plexiglas with a jigsaw is easy, and it is the best way to go. A jigsaw will be more efficient than other types of saws because it can be versatile when it comes to cutting Plexiglas.

While Plexiglas is brittle and fragile, following my guide will show exactly how you can cut through it with a jigsaw without breaking or even cracking the sheet.

You May Also Like:

1. How To Cut Plexiglass On A Table Saw – Learn With Different Saws

2. How to Cut Plexiglass with a Circular Saw -Expert DIY Guide(2020)

Table of Contents